1. R&D, Get Your

Best Bike Model

Bikes emphasize a lot on designs. A good model contributes at least halfly to your achievements.

2. Full series undercontrolled manufacturing

Main producing procedures all in our own factory and under controlled.

Welding

Four frame welding lines and four fork welding lines. Mostly are 1.0T and 1.2T with TIG welding

Pretreatment

We have the biggest sand blast machine to clear the surface and prepare them for painting

Painting and Coating

Two painting lines for frame and forks and one coating lines for spare parts. Stickers on the line.

Assembly

Automatic wheel group lines and assembly lines are neck to neck, fast and scraches avoided

Packing

SKD 95% for retailers, SKD 85% for distributors, CKD for customers with assembly labors

Warehousing

All finished goods packed on pallets by orders, technique keepers appointed

Qualified QC

Totally 6 people with a manager above 17 years experience, those below 2 years can't work alone.

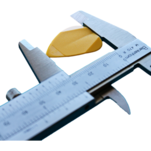

Specialized Tools

Full series of special tools ready for quality inspections, and all QC people are trained to use them.

SOP

Detailed directions on each step inspections are supervised to be implemented

All Procedures

Self-chcking in each procedures from parts, welding, painting, assembly and completed bikes

Feedbacks

Specifications adjusted according to market feedbacks to make new standard

Backup

All this files will backuped for better services in future cooperations

3. Professional and Systematic

Quality Control

Quality is of first priority and sentific control is a must

4. Delivery is a

technique too

Well masted delivery can save you both time and money, and avoid troubles.

5. After-Sale Supports

We are together with the new cycle of business after your received the bikes